Aluminum Extrusions

Both Humans and Robots love welding precision cut extrusion.

Available Aluminum Alloys

6005 (T4-T65)

6061 (T4-T65)

6063 (T4-T65)

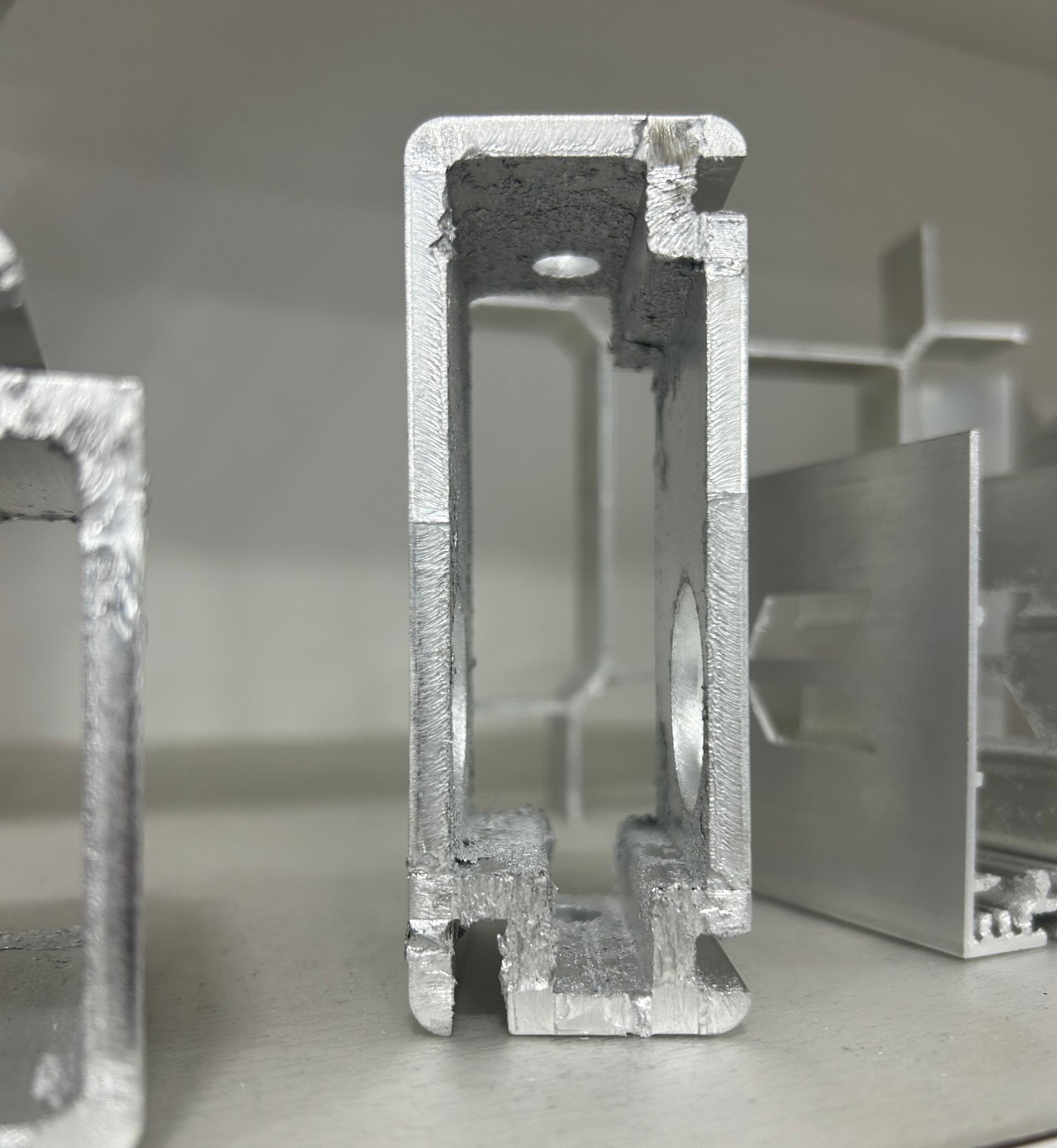

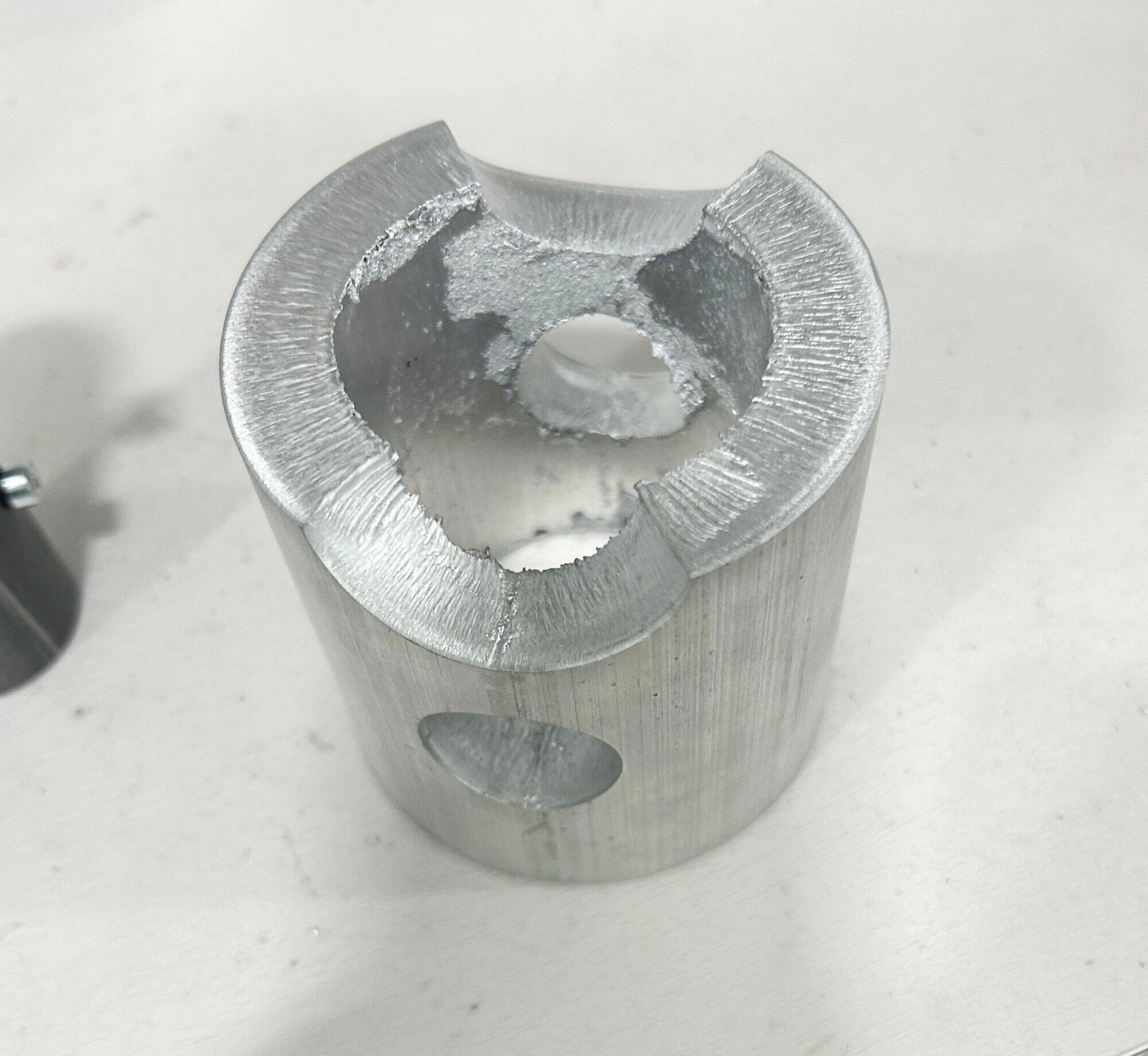

What Extrusions can be cut?

Most open profiles can be cut as well as closed profiles with odd features around the outside perimeter. To the right is an example of a relatively complex extrusion that was cut on a Tube Laser.

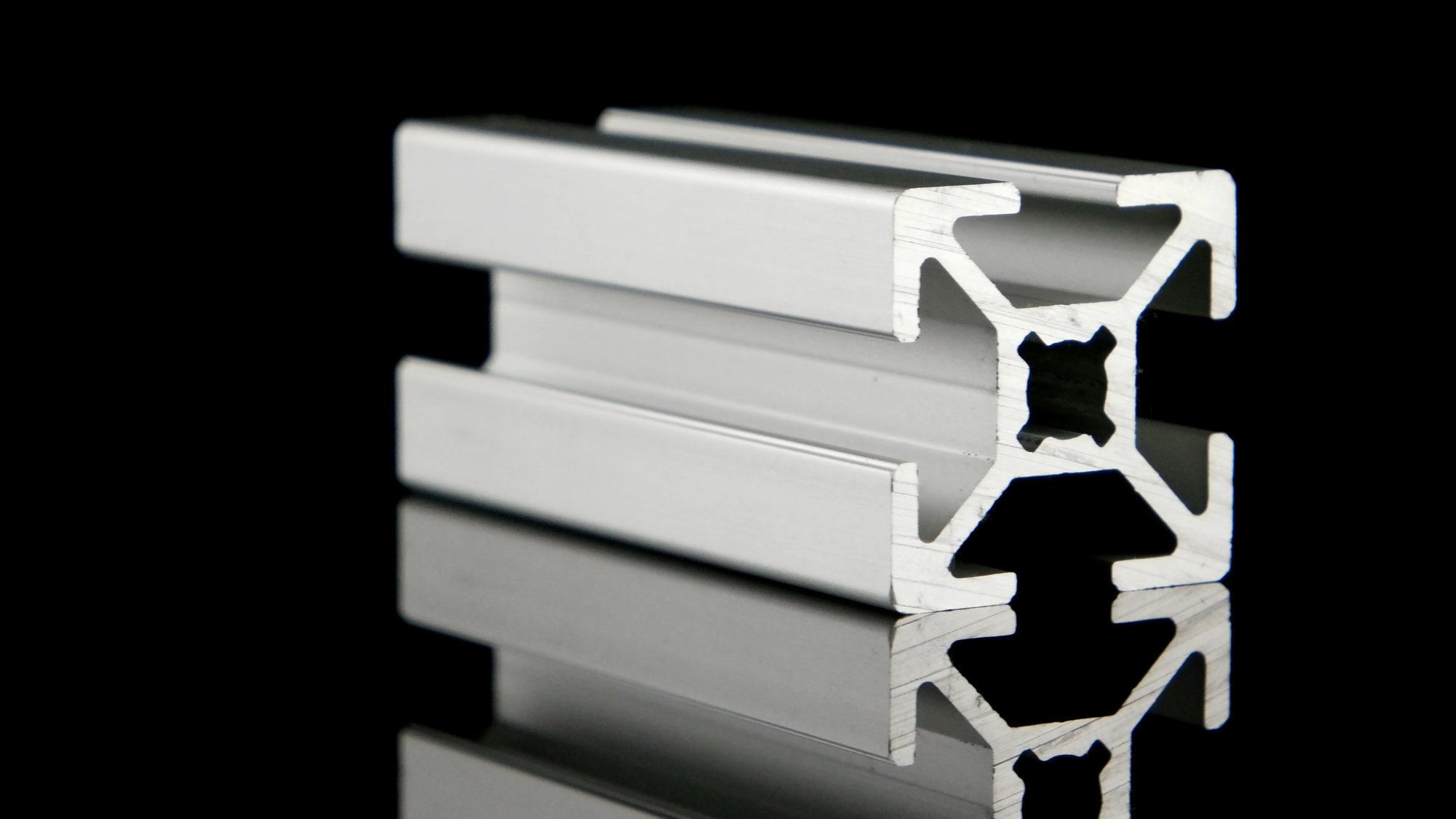

What Extrusions can't be cut?

Closed profiles with complicated webbing or thickness that cannot be reached with the head of the laser. For example, the laser cannot reach into the small openings in a T-Slot extrusion, so it is unable to be processed on a Tube Laser.

Still not sure? It's complicated, we can help you figure it out!

Laser Cutting = Cost Savings

If an extrusion can be cut on a Tube Laser, it is guaranteed to process much faster than milling. This means big cost savings and shorter lead times.

Technical Capabilities

Equipment Specifications

| Specification | Value |

| Laser Type | 2k Fiber |

| No. of Controlled Axes | 4-Axis |

Workpiece Specifications

| Specification | Minimum | Maximum |

| Outside Diameter (in.) | 0.472" | 4.724" |

| Maximum Material Weight (lbs per ft.) | 10.34 lbs/ft. | |

| Maximum Material Weight (total lbs.) | 220 lbs | |

| Finished Part Length (in.) | 1" | 177" (14' 9") |

| Tolerances | ±0.003" | |

| Maximum Wall Thickness (in.) | ||

| Aluminum | 0.25" |

Software Specifications

| Specification | Value |

| Programs Used | Solidworks |

| File Types Supported | STP | STEP | SLDPRT | Adobe |